Table of contents

- Key Takeaways

- Understanding Brad Nailers

- Understanding Finish Nailers

- Comparing Brad Nailers and Finish Nailers

- Factors to Consider When Choosing Between a Brad Nailer and Finish Nailer

- Pneumatic vs Cordless Nailers: Which is Right for You?

- Tips for Using Brad Nailers and Finish Nailers Safely and Effectively

- Summary

- Frequently Asked Questions

As a woodworker, I hate using the wrong tool for the job. The work is more difficult, setup is usually trickier, and the results simply aren’t as good. The choice between a brad nail and a finishing nails is one of those times.

Here’s why it matters:

- You’ll be using one of these during the last stages of your work. If you split wood at that point, it’s usually a time-consuming repair.

- Most brad nailers are great for thin wood where the smaller nail heads won’t make such a visible hole. A finish nail is (slightly) bigger and is used for attaching thicker wood, like installing baseboards and door trim. Grabbing the wrong tool for the job makes a DIY project more difficult.

- Your budget also matters, especially if you can only buy one tool. A finish nailer could be used for projects when you need brad nails, but the opposite is not true. Of course, bigger nails could mean more wood filler, but that’s possible for most DIY projects.

Those reasons, and more, are why I think it’s best to think about what you want and then buy the right tool.

Key Takeaways

- Brad nailers use delicate 18-gauge brads suitable for lightweight, delicate projects to avoid splitting wood, while finish nailers use larger 15 or 16-gauge nails for stronger holds in heavy-duty tasks.

- Finish nailers are preferred for projects requiring a robust hold like baseboards, crown moldings, and dense materials, whereas brad nailers are ideal for tasks needing minimal visual impact and finesse.

- Proper maintenance and observing safety precautions are crucial for both brad nailers and finish nailers, ensuring their longevity and the safety of the user.

Understanding Brad Nailers

Tools known as brad nailers are designed to secure thin nails called brads into wood. These particular instruments come in handy for light decorative trim projects due to their minimalistic touch. A brad nailer makes tiny holes that prevent the material from splitting. These items tend to be a top choice when finesse is important. The 18 gauge size makes the tiny nails perfect for delicate trims or decorations that require precision – such as furniture building or finish carpentry tasks – so they can help add an extra special detail without damaging anything else nearby!

Characteristics of Brad Nailers

Brad nailers feature adjustable depths and are known for their versatility in providing precise control over the penetration of nails into different materials. These tools also boast a lightweight design, which allows you to move easily when working with accuracy.

These thin brad nails can be used together with glue as well for creating an even stronger bond than usual. They work like a clamp until the glue dries up completely! So they’re perfect for light-duty finish carpentry projects or any delicate woodwork.

Common Applications for Brad Nailers

When it comes to a comparison between the brad nailer and other tools, the small nails produced by these nailers offer minimal holding power but leave barely visible holes. Depending on the finish and presentation, the holes might not even require filling before painting. This makes them an ideal choice for delicate projects that need only light-duty finish carpentry work so as not to cause any split in wood or trim.

Understanding Finish Nailers

Finish nailers, the tools designed for accommodating 15-16 gauge nails and giving more power to hold materials firmly in place, are popularly used when heavy duty fastening is needed. These types of nailers offer a much stronger grip than brad ones, which makes them a go-to tool for heavier material projects.

Characteristics of Finish Nailers

Finish nailers offer exceptional capabilities when it comes to tough materials such as hardwood and MDF. They make use of larger nails with greater penetration, making them perfect for thicker pieces of wood.

For a polished end result, most models are equipped with depth adjustment settings which allow the user to manage exactly how deep the nail is inserted into their workpiece – so there’s no excess protruding from the surface.

Common Applications for Finish Nailers

Finish nailers are a great choice for projects involving strong fastenings and hard materials, such as attaching crown molding, baseboards and door casings using nails with headpieces. The larger diameter nails hold better when glue isn’t an option.

In homes, finish nailer use can be seen when installing things like trim around windows or doors that need added support. Beadboard on porch roofs may also require these helpful tools in order to ensure sturdy nailing capability.

Comparing Brad Nailers and Finish Nailers

Brad Nailers and Finish Nailers may look alike, but they are different tools when it comes to nail size, gripping strength and the kind of task that they are suitable for. Brads have a smaller head and diameter than finish nails but can provide enough hold due to their higher number per inch. On the other hand, Finish Nails offer more holding power despite the fact that they offer more holding power.

Nail Size and Holding Power

When looking at a brad nailer versus a finish nailer, it is the size of the nails that mainly distinguishes them. Brad nailers take 18-gauge nails which are thinner than their 15 or 16 gauge counterparts used in most finish gun models.

The ability to hold materials securely differs between these two types due to the thicker profile and superior gripping power provided by larger diameter finisher’s nails compared with those from a standard brad model. This should be kept in mind when deciding on an appropriate tool for your next project as both have different advantages depending on what job you require them for.

Project Suitability

When it comes to choosing the correct tool for a project, brad and finish nailers offer distinct advantages. Brad nailers are best suited for smaller projects such as trim work or moldings due to their small-headed nails that can prevent wood splitting when creating shallow holes.

Finish nailers provide superior holding power with larger 15 or 16 gauge nails ideal for door frames, window trims, baseboards and other heavier materials requiring more substantial hold than what is offered by brads alone.

Pros and Cons

When making a decision between brad and finish nailers, it’s important to consider the benefits that each offers. Brad nailers offer unparalleled accuracy. To small holes but lack when compared against finish nails’ holding power. On the other hand, while more bulky than its counterpart due to the thickness of nails used (with potential for deflection as well as larger sized holes existing), using a finish nailer provides better durability on heavier projects.

Factors to Consider When Choosing Between a Brad Nailer and Finish Nailer

When choosing between a Brad Nailer and a Finish Nailer, one must take into account the project’s specifics, material thickness as well as budget. All these aspects are of utmost importance for arriving at an informed decision that suits your needs.

Project Type and Material Thickness

When it comes to tasks that involve lightweight, softwood finishing carpentry projects, the brad nailer is a preferred option. 21 gauge brads are typically used when working with materials of thinner dimensions. Conversely, those wanting a tight grip on larger jobs such as cabinet assembly and woodworking should lean towards employing finish nailers. These can easily fasten hardwoods and other denser elements like MDF boards securely in place without difficulty.

Budget Considerations

When selecting between a Brad Nailer and a Finish Nailer, budget is an important factor. A typical cost for brad nailers falls in the range of $50 to $300 with boxes containing nails costing from about 10-30 dollars each. Not only does one need to consider price, but other expenditures such as maintaining tools like cartridges (for pneumatic models) or battery replacement (cordless ones). The same applies when deciding on purchasing finish nailers. You’ll have additional expenses e.g., renting costs and batteries replacing requirements if it’s cordless model type used.

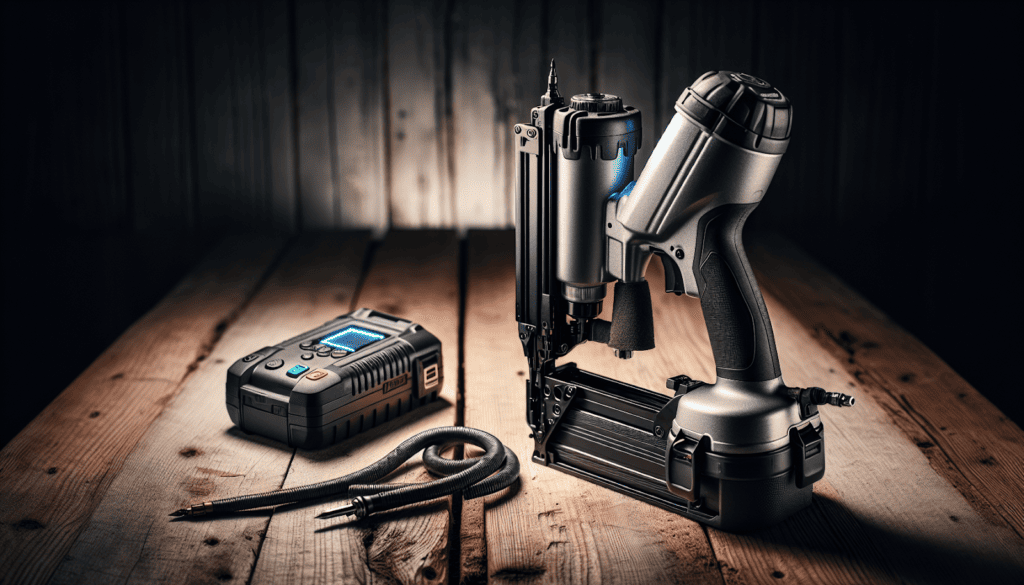

Pneumatic vs Cordless Nailers: Which is Right for You?

A choice between a Brad Nailer and a Finish Nailer is important, but also deciding if you would prefer a pneumatic or cordless nailer can be just as critical. This decision should take into account what meets your requirements best along with personal preference, both have their own advantages and disadvantages to consider.

Advantages and Disadvantages of Pneumatic Nailers

Pneumatic nailers use compressed air from an air compressor, allowing them to continue working as long as the compressor stays connected. These tools are often considered cost-efficient with finishing and framing models running anywhere between $20-$2,000 and $30-$500 respectively. They tend to be louder than other kinds of machines due to their compressors, plus there can sometimes be challenges when it comes to tangled hoses or tripping hazards posed by them too.

Advantages and Disadvantages of Cordless Nailers

Cordless nailers offer convenience to DIY users, though they tend to be more expensive. The advantage of these over pneumatic versions is the elimination of gas fuel cells, making charging and use much simpler. Also, cord-free tools enable projects without constraints on movement while being portable at the same time.

Due to their battery packs for powering them up regularly. Weight can become an issue if there’s extensive usage as it could cause exhaustion with prolonged periods or workmanship involving a lot of holding up such devices.

Tips for Using Brad Nailers and Finish Nailers Safely and Effectively

For the maximum benefits of your Brad Nailer or Finish Nailer and to guarantee a secure environment, following specific guidelines is crucial. Such rules include making sure that your nailers are kept in top condition as well as strictly adhering to safety standards.

Proper Tool Maintenance

Prolonging the life of your nailer is achievable through routine maintenance. For brad-style models, this includes clearing out the feed system and using lubrication to ensure proper functioning, followed by shooting a few nails as required. Meanwhile, finish gun upkeep involves regular oiling, cleaning if necessary, and setting up its features per requirements.

Check-ups should be made on occasion so any signs of damage or wear can quickly be noticed and damaged parts swapped in exchange for new ones without delay – all these measures contribute to solid tool performance over time.

Safety Precautions

Operating a nailer requires utmost safety. Both brad and finish types of these tools come with built-in mechanisms that make it difficult to cause any unintentional damage while working, such as triggers featuring special guards.

To protect yourself fully, you must always put on the necessary PPE when operating a nailer: protective eyewear so your eyes are protected from particles and strong gloves for protecting your hands. Ensure cleanliness in order to decrease risks associated with tripping or other accidents related incidents while using an instrument like this one.

Summary

In deciding between Brad Nailers and Finish Nailers for your project, the type of material you’ll be using and the cost should all be taken into account. Although both types come in pneumatic or cordless models, Brad nailers are designed for delicate jobs that need a gentle touch due to their smaller size nails while Finish nailers’ larger nails provide more strength when tackling heavier-duty tasks.

Frequently Asked Questions

What is better a brad nailer or finish nailer?

When it comes to woodworking projects, the choice of nailer type depends on what you are trying to achieve. A finish nailer is ideal for larger carpentry tasks such as crown moulding, while a brad nailer can be employed for more delicate applications and thin trim or other forms of ornamentation. Deciding which one best fits your project’s needs is up to you!

Can you use a brad nailer for finishing?

You can use a brad nailer for finishing on one condition: your nails hold the finished product securely. If you’re using heavier wood, hardwood, or a high-movement piece, then a brad nailer is only going to work with glue to provide the strength needed. Even then, tough woods or thicker woods will simply jam your brad nailer.

What kind of nail gun for baseboards?

Using a nail gun and finish nails, which come in 15 or 16 gauges for bigger pieces such as baseboards, is the ideal way of attaching trim to your walls. A brad nailer will not provide the strength needed and might struggle with the hardwood some baseboards are made of.

What are the advantages and disadvantages of pneumatic nailers?

Pneumatic nailers are cheaper and don’t ever need recharging. But they do need an air compressor and power supply for the air compressor. If you don’t already have these, the combined cost will probably be more than the battery power tool.

What are the advantages and disadvantages of cordless nailers?

Weighing the pros and cons, cordless nailers offer convenience in their portability, but they can also be heavier than pneumatic tools, which could lead to greater fatigue for longer jobs. Cordless nailers also need recharging, which could be a problem for a big job or an in-demand professional.

I’m happy to see a very well written explanation on the difference between brad & finish!

Now…my question….

I’m going to be lining my closet with cedar flake panels and redoing a the (crappy standard contractor grade) moulding and door/window frames (moulding, more accurately) with my preference..fake wood…super light weight.

Yes, there ARE many reasons for this which are irrelevant ….my question then is brad or finish?

My gut says brad.

Thank you in advance!

Nothing holds to drywall, You always have to hit wood. For baseboard slightly angle the 18ga 2 1/8″ brad downward to pick up the 2×4 sill plate. For crown fasten a nailing block behind to nail to. Never just to drywall.