The best table saw is designed with the purpose of cutting wood in mind, but that doesn’t mean it has to stop at only cutting wood. Along with all sorts of wood, it can cut various types of plexiglass, PVC piping, styrofoam, and cardboard. But what about more durable materials like metals?

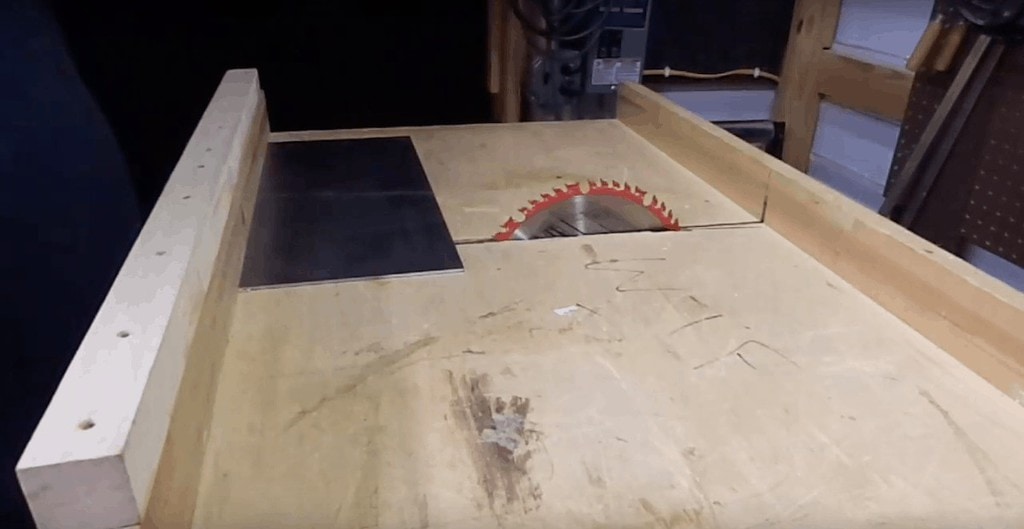

The question is: can you cut aluminum with a table saw? Yes. You can cut aluminum with a table saw, but it is not good for very thin aluminum sheet metal, and it is not the safest saw to use because of the risk of kickback.

Cutting aluminum is not as simple as cutting some of these other materials. It poses a real safety risk and some preparations must be made to complete the cut safely and effectively. In this article, you will learn how to cut aluminum with a table saw as well as how to cut aluminum using other methods that are safer and more effective.

Table of contents

How to Use a Table Saw to Cut Aluminum

Aluminum comes in two varieties:

- Aluminum Plate Metal

- Aluminum Sheet Metal

The main difference between aluminum plate and aluminum sheet is the thickness of the metal.

A table saw can cut many thicknesses of aluminum, but it is not suitable for most thicknesses of aluminum sheet as aluminum sheet can be extremely thin.

In order to cut the thinner pieces of aluminum, you will have to use bench shears or electric shears.

Gauges 7 and 8 of aluminum sheet metals can be cut with a table saw with extra care but cutting anything thinner can be seriously dangerous. You really don’t want that piece of sheet metal to come shooting back at you.

This chart lists the gauge number and the thickness in inches of aluminum sheet metal.

Gauge and Thickness of Aluminum Sheet Metal

|

Gauge Number |

Thickness in Inches |

|---|---|

|

7 |

.1443 |

|

8 |

.1285 |

|

9 |

.1144 |

|

10 |

.1019 |

|

11 |

.09074 |

|

12 |

.08081 |

|

13 |

.06408 |

|

14 |

.05082 |

|

15 |

.04030 |

|

16 |

.03196 |

|

17 |

.02535 |

|

18 |

.02010 |

|

19 |

.01594 |

|

20 |

.01264 |

|

21 |

.01003 |

Additionally, if you are cutting thicker pieces of aluminum, you should be sure that your motor is strong enough to handle aluminum of this thickness. If your table saw doesn’t cut through thick pieces of hardwood like butter, it isn’t going to do any better with aluminum.

Supplies Needed

Ear Plugs

Work Gloves

Eye and face protection

Blade for Non-Ferrous Material

Push tool

Metal File, Deburring Tool or Scotch-Brite Pad

Blade Selection

The blade you need will really depend on the thickness of the material. In most cases, a standard non-ferrous blade will do just fine on most aluminum, but as you approach thinner dimension, you should reduce the number of teeth your blade has.

This chart breaks down how many teeth per inch of diameter you will need on a blade to cut through different aluminum thicknesses.

Teeth per Inch of Diameter Needed for Aluminum of Different Thicknesses

|

Thickness of Aluminum |

Teeth per Inch of Diameter |

|---|---|

|

⅛ inch |

10 |

|

⅛-¼ inch |

8 |

|

Thicker than ¼ inch |

6 |

(Source)

If the aluminum is less than ⅛ of an inch thick, you should not use your table saw to cut it.

Step-by-Step Process of Cutting Aluminum with a Table Saw

- Start by unplugging the table saw.

- Carefully, take off the blade you usually use for cutting wood.

- Replace that blade with a blade meant for non-ferrous materials. If your table saw allows you to install a smaller blade, use a 7 ¼ inch blade.

- Lubricate the blade using a beeswax or paraffin wax. You can wax the tabletop to make the metal slide across the table smoothly.

- Adjust the speed of the arbor, if possible. The recommended speed is 750 FPM to 1500 FPM.

- Put on your eye and face protection, ear plugs, and work gloves.

- Plug the saw back in.

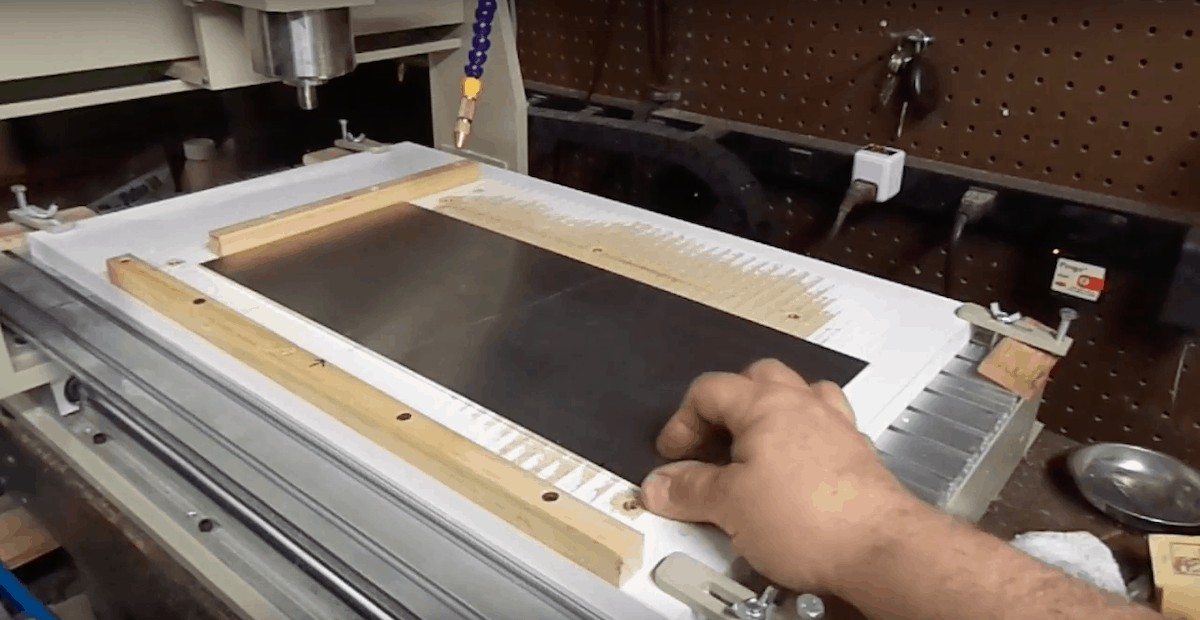

- Place the piece of aluminum on the table saw. Stay out of the kickback zone. Operate the saw as you normally would with wood with one exception — move the metal slowly into the blade.

- When you have finished the cut, turn off the table saw.

- If you need to smooth or straighten out rough edges you can use a standard file, deburring tool, or a Scotch-Brite pad.

Disadvantages of Cutting Aluminum with a Table Saw

While a well-powered table saw will cut through metal, it is not always the saw of choice for frequent metal cuts. Here are some reasons you might choose to go with a different saw.

Metal Shavings

The most common complaint people have about using a table saw to cut metal shaving is the amount of metal shavings that get everywhere. The fly off the saw blade as you are cutting and get all over the table, and many will fly up toward your face.

This is not only uncomfortable, but downright dangerous, which is why it is recommended that you use face protection when cutting aluminum with a table saw.

These sharp metal shavings also make clean up a real pain. You can’t just brush the shavings away with your hand. You could try compressed air, but it might not be effective if the shavings are larger. A soft bristled brush and dustpan may need to be used to get them off your saw.

Changing the Blade

If you’ve given up on wood completely, this likely won’t be much cause for concern, but If you still want to use the table saw for wood, you will have to frequently swap out the blade.

Changing out the saw blade isn’t a big deal, but it can get cumbersome to have to switch back and forth between blades, especially if you’re in a time crunch.

Kickback

Kickback is a serious hazard when using a table saw no matter what material you’re cutting, but since you are using a table saw to cut a material that it was not designed to cut, the risks are greater.

If you are going to use your table saw to cut aluminum, you might want to give it a tune up first and make sure all the pieces are properly aligned. Check the blade and the fence should both be parallel to the miter slot, and the splitter should sit precisely behind the saw blade.

In addition, make sure the safety guard is properly installed and that you use a push tool to move the metal into the blade. The push tool is meant to keep your hands and the rest of your from being pulled into the blade.

Finally, check your position and the position of those around you. Make sure no one is standing in the kickback zone. When a material kicks back it typically shoots directly behind the saw… the location where most people stand while using the saw.

Other Tools to Cut Aluminum

Assuming you are using the right blade, you can use a chop saw or a miter saw to cut aluminum. Both of these saws often come with dust collectors which will help to keep those shavings from flying all over the place.

Electric shears can cut aluminum sheet metal up to ⅛ of an inch thick. Electric shears cut thin pieces of aluminum without distorting the edge and without any metal shavings flying at your face, and they have the added benefit of being more portable than a table saw.

Bench shears can also cut aluminum sheets up to ⅛ of an inch. These are generally better for smaller pieces of metal. If you have longer pieces of aluminum sheet metal that you want to cut then you might want to stick with electric shears.