Whether you found a good deal on a pre-owned table saw, your moving to a new house, or your just moving job sites, moving a table saw is a daunting task, but it isn’t as difficult as you might think. In this post, we'll explain how to transport a table saw.

To transport a table saw, you need to remove any pieces of the table saw that can be removed this includes the extension wings, fence rails, the cast iron top and the motor if it can be removed. You can then load the pieces one by one into the back of a truck or trailer.

» COMPARE: Full Table Saw Buyers Guide

Transporting a table saw is no simple task, but it isn’t impossible. In this article, I will share some tips for getting your table saw from point A to point B.

Transporting a Stationary Table Saw

Stationary table saws can easily weigh over 300 pounds, they are large, they are top heavy, and they are just plain awkward. Moving one of these beasts takes some effort, but it can be done.

Supplies

Here are some things you might need to help you move a stationary table saw.

Owner’s Manual

Tools for taking the table saw apart

Moving dolly

Hand cart

Moving blankets

Ratchet straps

Friends

Take it Apart

Your probably don’t want to take your table saw apart to move it, especially if you didn’t put it together, but if it is a heavy model, then it is really the safest way. By taking some of the heavier pieces off the table saw and loading them on the truck separately, you will significantly reduce the weight of the saw.

The job of moving the table saw will become much easier. You don’t need to take apart the entire table. Removing the any extension wings, fence rails, the cast iron top, and the motor will probably be enough to make the rest of the table saw portable.

Refer to your owner’s manual on how to locate the bolts you will need to remove and keep it handy when you’re ready to put the pieces back together. If you do not have an owner’s manual, you can usually find them online on the manufacturer’s website.

This chart shows just how much weight you can take off the table by comparing three different SawStop table saws.

Name of SawStop Saw | Weight of Saw | Saw and 30’ Fence System | Cast Iron Wings |

|---|---|---|---|

SawStop Contractor Saw | 225 lbs. | 245 lbs. | 35 lbs. each |

SawStop Professional Cabinet Saw 1.75 HP | 317 lbs. | 367 lbs. | NA |

SawStop Professional Cabinet Saw 3 HP | 335 lbs. | 380 lbs. | NA |

Removing any cast iron wings alone can save you at least 35 pounds and removing the fence rails can save 20 pounds on a contractor saw and 50 pounds on the cabinet saw.

Additionally, removing the motor can make a big difference, especially if the motor is powerful. You can see in the chart that the difference in weight between 1.75 HP Cabinet saw and the 3 HP is 18 pounds.

Of course, how much weight you can take off your load will depend on how heavy the individual components of your specific table are.

Get Help

If a strong friend owes you a favor, now is the time to call it in. Moving a table saw by yourself is sometimes possible if you have a moving dolly, a ramp to the truck, and you do not need to go up or down stairs, but no matter what, having a spare set of hands is going to make the whole process go more smoothly.

Even simple tasks, like holding open a door, when you’re moving a two hundred-pound, top heavy table saw can be difficult without help.

Protect the Pieces

The last thing you want to do is damage the saw or your truck will you are moving the table saw. Prevent damage by laying out thick moving blankets, cardboard, or carpet in the bed of the truck you are using to transport the table saw.

You should also wrap all the pieces you took off the table saw in moving blankets or some other protective covering.

Ratchet Straps

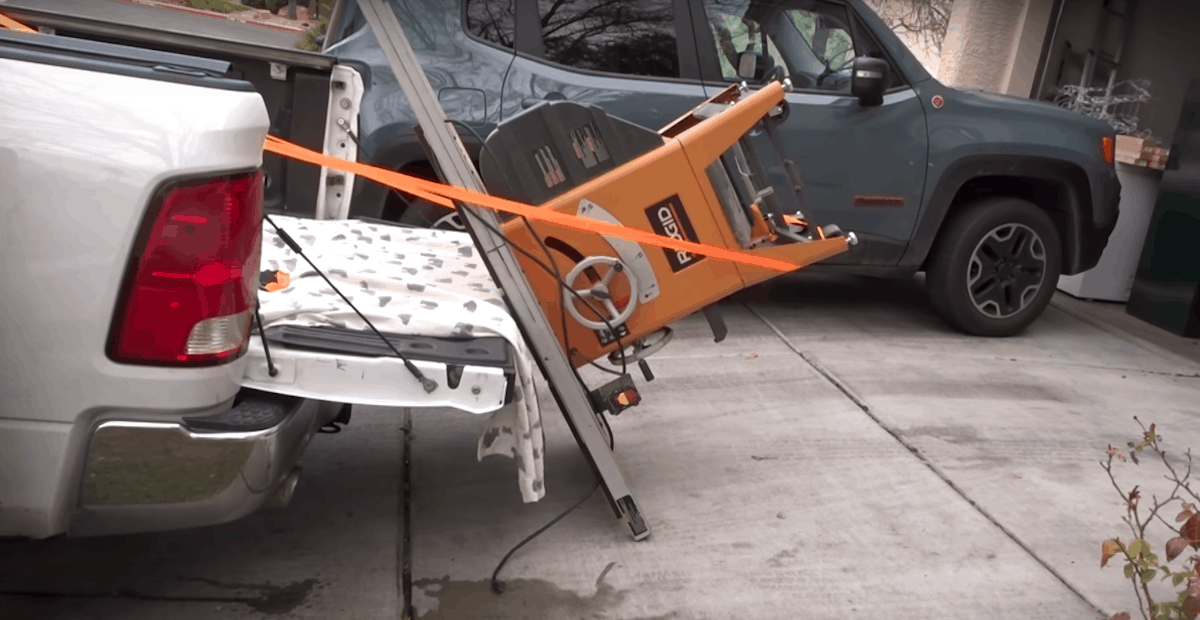

All of the pieces you load onto the truck should be strapped down or otherwise secured to prevent them from rolling around the back of the truck.

Use ratchet straps or ropes to secure each piece of equipment so that is does not bump around, become damaged, or fall off the back of your truck.

In addition, it is important to lay the table saw on its side or upside down because table saws are top heavy. If you leave the table saw upright, it will be prone to tipping over in the back of your truck.

Loading the Saw on to the Truck

If you’ve taken the table saw apart then it is very likely that with the help of a friend or two, you will be able to lift it onto the back of the truck.

But if you cannot lift the table saw on to your truck, there are a few options:

Loading Ramp

If you’re trying to load the table saw onto the back of a pick-up truck, you may want to invest in a loading ramp. A loading ramp can be a useful truck accessory to have around anyway, if you frequently need to lead heavy items.

Alternatively, you can build your own loading ramp using plywood, 2x4s, 1x6s, and a handful of hardware like this person did or you could rig up your own plywood ramp. Just make sure it is secure and sturdy enough to hold the saw.

Trailer

If you’re having trouble lifting the table saw high enough to get it on the back of a pick-up truck, then you might consider renting or borrowing a trailer. Trailers are generally lower to the ground than a pickup truck, and often have ramps or the ability to tilt to the ground.

Be sure that you strap the table saw to the trailer securely.

Moving Truck

It might cost a little extra but renting a moving truck can make the job much easier. Most moving trucks come equipped with ramps, and if you don’t have a hand cart, you can rent one of them too.

Some companies even offer moving trucks with hydraulic lifts that will make moving that heavy table saw easy as pie.

Transporting a Portable Table Saw

Portable table saws (also called job site table saws) are designed to be easily moved. Many of them are lightweight or they come with carts that allow them to be rolled on to the back of a truck or trailer.

If you do not have a ramp available, portable table saws are usually light enough to be lifted by two people.

The only trouble is that table saws are almost always top heavy. If this is the case with your portable table saw, you may need to remove the table saw from its base when transporting or lay it on its side or upside down if they design allows for that.

Be sure to strap the table saw to whatever you are using to haul it so that it does not get damage or cause damage to your truck. If you need to move your table saw around frequently, you may want to invest in ratchet straps as they make strapping equipment down simple.

No matter how you decide to go about transporting your table saw, it should be done with careful planning and the help of at least one other person to do it safely and without damaging the saw.